1.Comprehensive Compatibility:

The machine is not only capable of producing mainstream capsules such as Keurig k cup and Nespresso, but also handles Dolce Gusto, Lavazza, paper cups and a wide range of customized shapes. This all-round compatibility makes it ideal for different market needs, providing customers with a more diverse product portfolio.

2.Mechanical Linkage Structure:

By utilizing top European design concepts, the machine achieves industry-leading levels of structure and performance. The mechanical linkage design concept not only improves stability, but also increases the reliability and durability of the machine.

3.High-speed And Efficient Production:

As the fastest model available in China, this machine excels in high-speed production. Its high efficiency and stability allow it to adapt to mass production needs, providing users with faster production cycles and higher yields.

4.Continuous innovation and patents:

Our design team is committed to continuous innovation and pushing the boundaries of technology. In addition to the unique patents already in place, we are constantly striving to develop new technologies to ensure that our machines are always leading edge in performance and reliability.

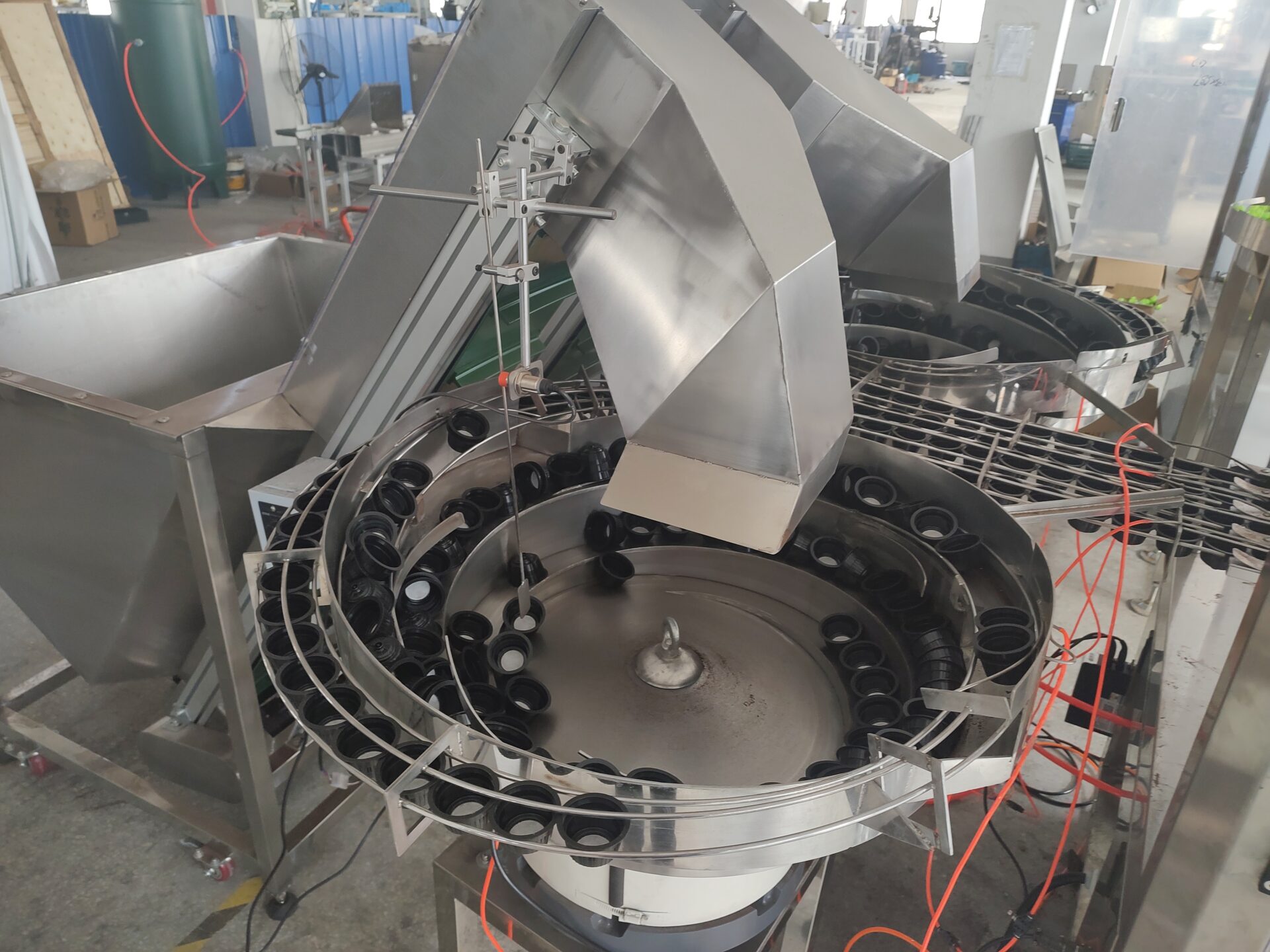

Special storage designs that can stockpile a large number of cups per time and automatically feed the cups to the packaging line. In addition, putting the capsules is very easily, it reduces the labor cost and time for filling capsules manually. Likewise, this system completely solves the common problem of stuck capsules and damaged capsules.

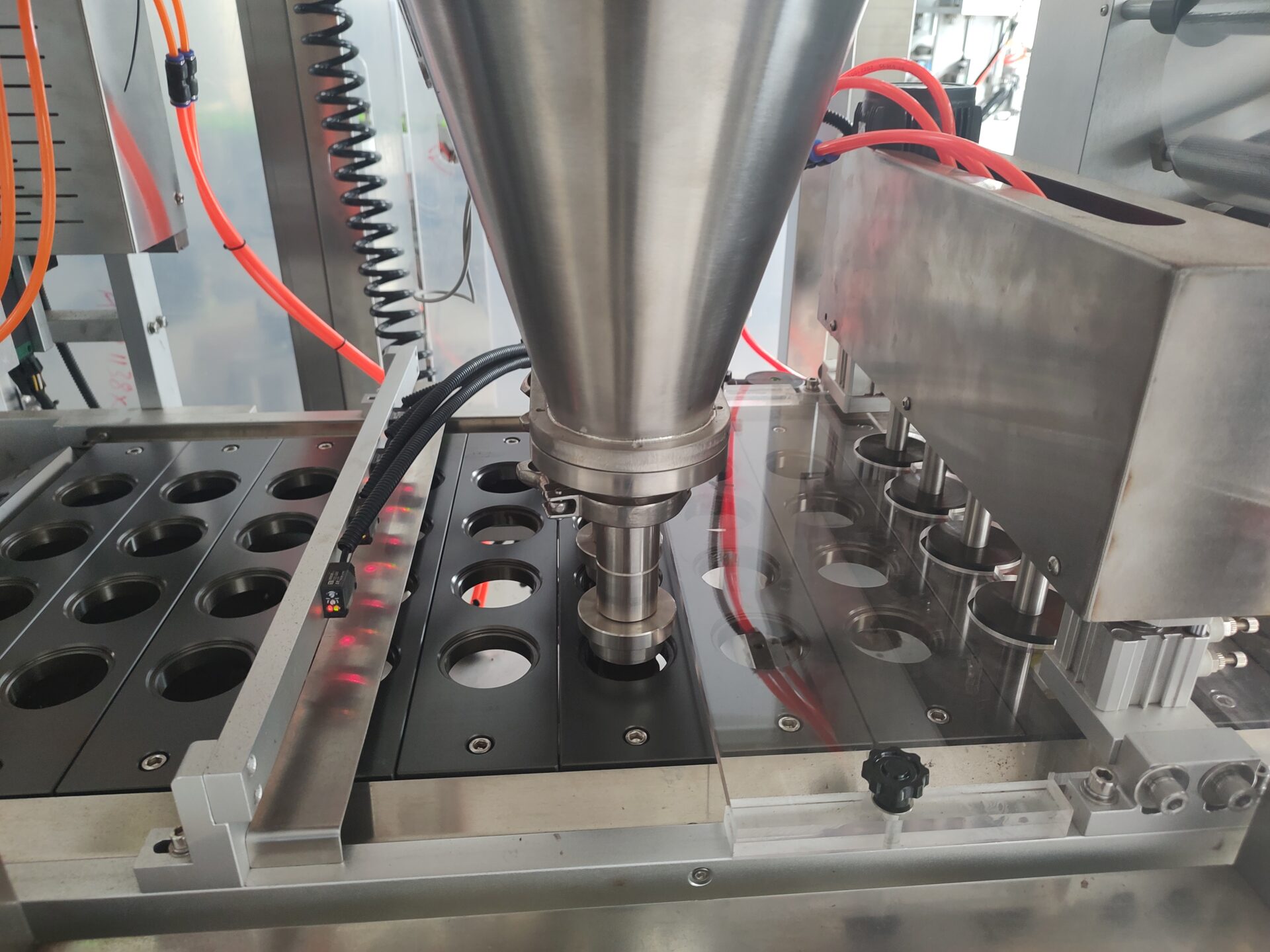

The auger filler in this machine has world highest precision that can reach 0.05 grams, furthermore it is leak-proof, which helps seal better. The material contact machine is all SS304; it meets the medical hygiene standards. Also, the barrel can be quickly disassembled and purified. The material of the barrel is stainless steel, it has the advantages of being resistant to cleaning, break and scratching.

Precision manufacturing process is adopted to ensure a high degree of consistency and precision in each sealing step. Introducing automation technology to make the sealing process more controllable and efficient. Introduced a double sealing mechanism to enhance the firmness of the seal through two sealing layers. This improves the sealing of the product, preventing leakage of liquids or gases, while enhancing the compression resistance of the closure.

The full range of compatibility makes it ideal for different market needs, capable of producing mainstream capsules such as Keurig k cup, Nespresso, etc., as well as handling Dolce Gusto, Lavazza, paper cups and a variety of customized shapes.

Technical Parameters:

| Model | HT-KJ400 |

| Product | Ground coffee |

| Parts Contact With Product | Foodsafe Stainless Steel AISI 304 |

| Capacity | (35-50)x4 capsules/minute |

| Feeding | Servo driven auger filling |

| Filling Weight | 0-20g |

| Filling Accuracy | ±0.1g |

| Power | 3Phase 220/380V 50/60HZ 4.5 KW |

| Air Supply | ≥0.6Mpa |

| Air Consumption | 0.1m³/min |

| Weight | 1500Kg |

| Dimension | 3600×900×2000mm |